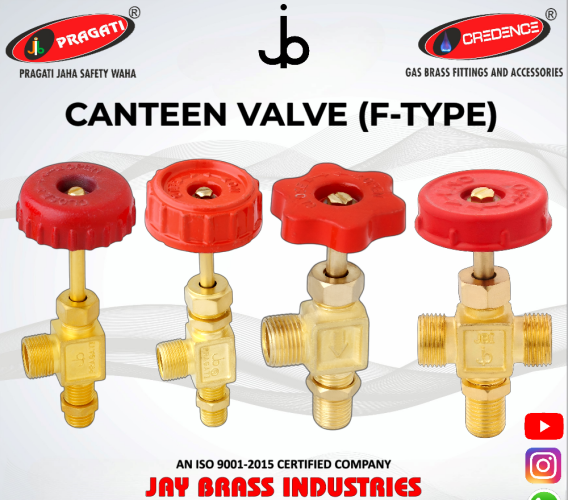

Canteen Burner Valve

52 INR/Piece

Product Details:

- Product Type Valve

- Usage For Burner Use

- Type Canteen Burner

- Material Brass

- Pressure Medium

- Handles Single Handle

- Threads Standard Threaded

- Click to View more

X

Canteen Burner Valve Price And Quantity

- 52 INR/Piece

- 1000 Piece

Canteen Burner Valve Product Specifications

- Standard Threaded

- Single Handle

- 0.15

- 15 mm

- Standard

- For Burner Use

- Gas

- Valve

- Canteen Burner

- Brass

- 12 mm

- Golden

- Medium

Canteen Burner Valve Trade Information

- Cheque

- 1 Piece Per Day

- 1 Days

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Africa

- All India

Product Description

| Actuation | Manual |

| Bonnet | Standard design |

| BRAND | PRAGATI |

| Certified | ISO |

| Color | Golden |

| Connection | BSP threaded |

| Stem | Threaded |

| Flow Control | Fine adjustment |

| Material | Brass |

| Power Source | LPG |

| Country of Origin | Made in India |

Sturdy Brass Construction for Longevity

Manufactured from premium brass and finished with a polished shine, this valve offers exceptional strength and resistance to wear. Ideal for busy kitchens, the material's natural corrosion resistance is enhanced by its quality surface finish, ensuring lasting performance even with heavy-duty daily operation.

Precision Control and Leak-Proof Operation

Engineered with a single handle and standard threaded screw connections, our canteen burner valve allows precise gas flow regulation. The advanced sealing technology ensures no leaks occur, safeguarding your kitchen and preserving fuel efficiency during operation.

Versatile Compatibility and Broad Application

The canteen burner valve is tailored for commercial kitchen equipment but can adapt to various settings requiring controlled gas flow. Its medium-pressure design, high resistance to corrosion, and adaptability to standard thread sizes make it a favored choice by distributors, exporters, and service providers across India.

FAQ's of Canteen Burner Valve:

Q: How does the canteen burner valve ensure leak-proof operation in commercial kitchens?

A: This valve features advanced sealing mechanisms and standard threaded screw-type connections, ensuring a tight, reliable fit that prevents gas leaks, crucial for safety and efficiency in professional kitchen settings.Q: What are the main benefits of using a brass, polished finish burner valve over other materials?

A: Brass offers superior corrosion resistance and durability, while the polished finish provides an easy-to-clean, aesthetically pleasing surface that withstands harsh kitchen environments, ultimately extending the valve's service life.Q: When should I replace the canteen burner valve in my kitchen equipment?

A: Replacement is advised if you notice irregular gas flow, difficulty in handling, or visible wear such as corrosion or thread damage. Regular inspections will help ensure consistent performance and safety.Q: Where can I install this burner valve, and is it compatible with all commercial kitchen burners?

A: The valve is designed for use with a wide range of commercial kitchen equipment that utilizes gas burners and standard thread sizes. Always confirm compatibility with your specific equipment model before installation.Q: What is the process for installing the screw-type burner valve?

A: Installation involves securely screwing the valve into the corresponding threaded port, ensuring a snug fit. It's recommended to use appropriate sealing material on the threads and check for leaks after installation before use.Q: How does the valve's operating temperature range benefit my kitchen operations?

A: With a temperature tolerance from -10C to 80C, this valve functions reliably in both cold storage or heated kitchen environments, accommodating diverse commercial cooking processes without compromising performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Brass Canteen Burner Valves' category

|

JAY BRASS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |