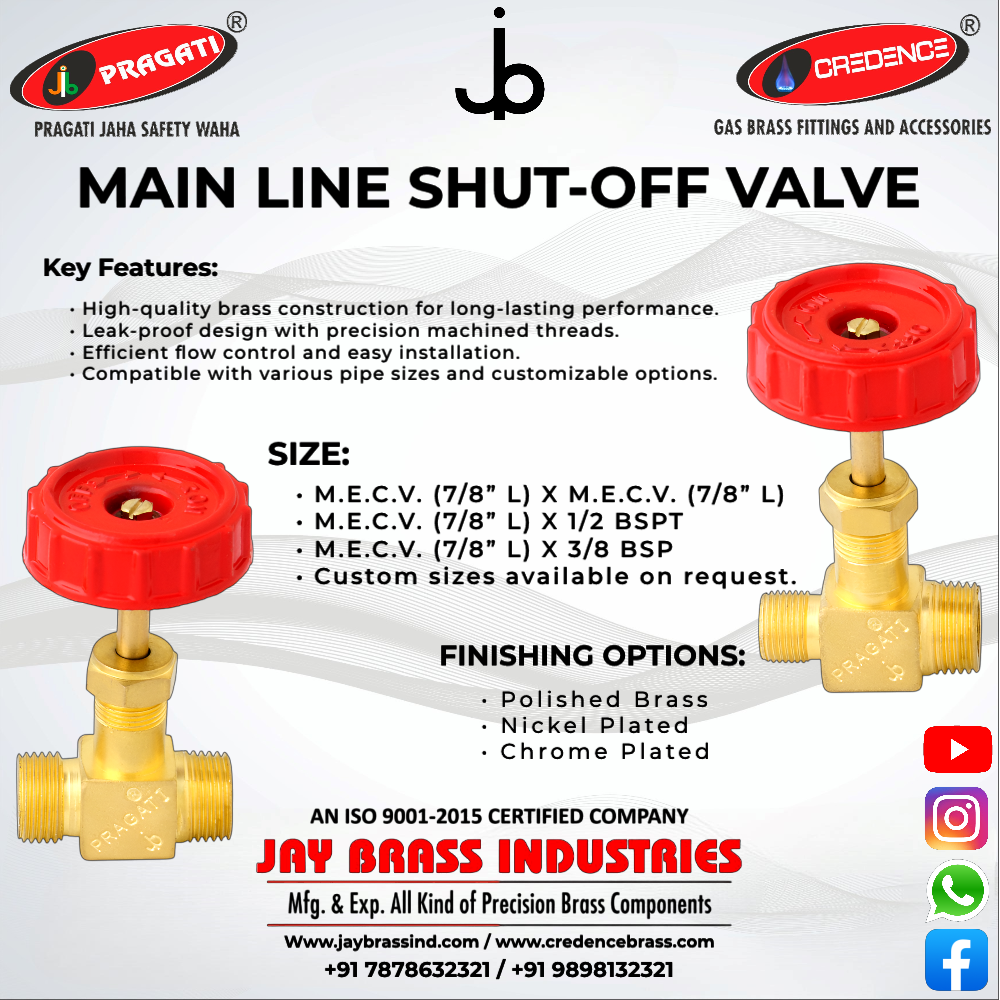

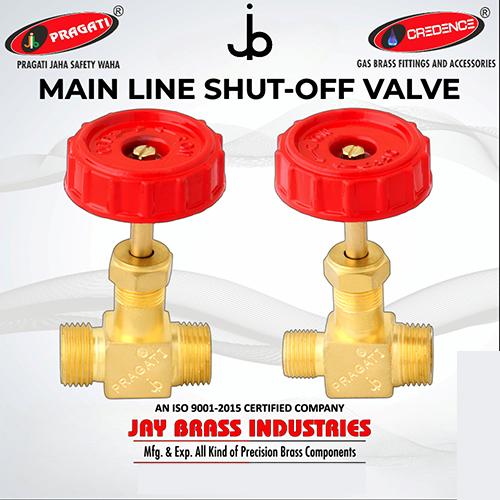

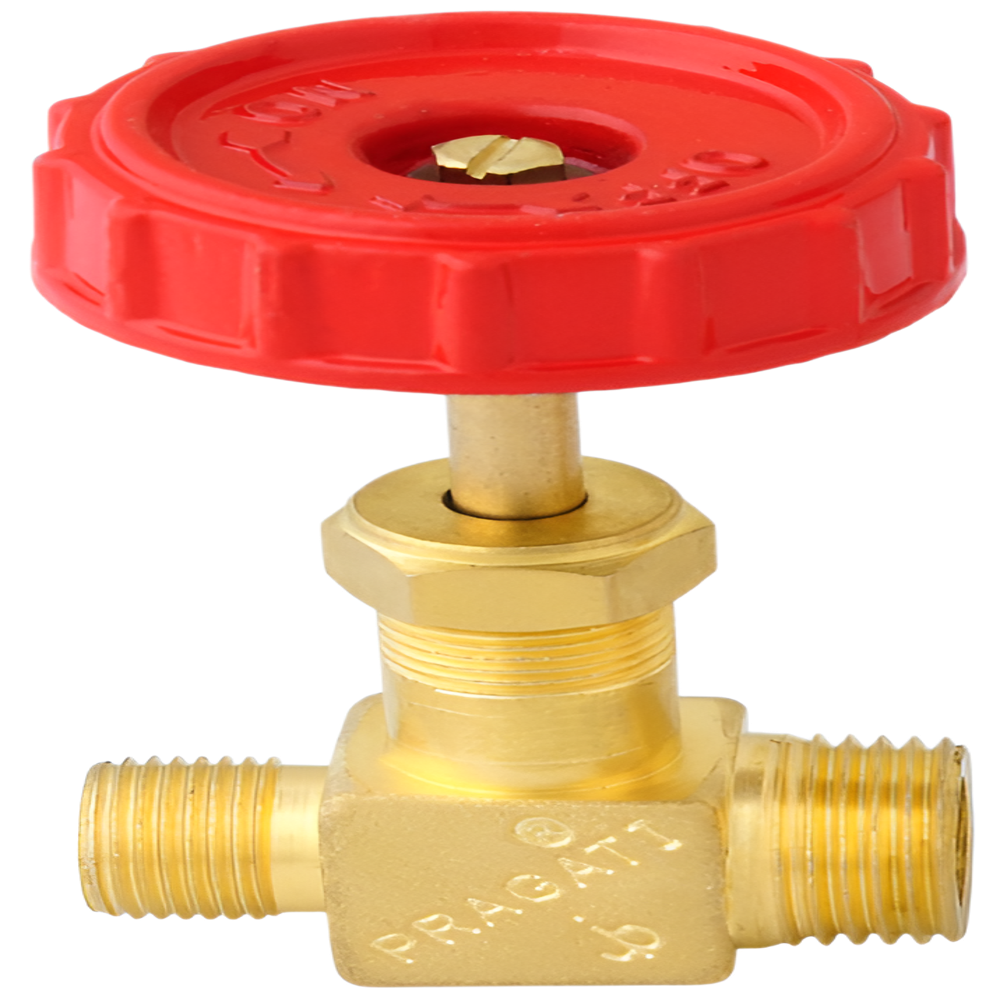

Main Line Shut Off Valves

Product Details:

- Material Metal

- Standard IS Specification Compliant

- Weight 10-150 Grams (g)

- Drawing Available on Request

- Material Capabilities High Pressure and Corrosion Resistance

- Type Main Line Shut Off

- Tolerance 0.05 mm

- Click to View more

Main Line Shut Off Valves Price And Quantity

- 219 INR/Piece

- 500 Piece

Main Line Shut Off Valves Product Specifications

- Polished

- Available on Request

- Valves

- High Pressure and Corrosion Resistance

- 0.05 mm

- Main Line Shut Off

- IS Specification Compliant

- 10-150 Grams (g)

- Golden

- Metal

Main Line Shut Off Valves Trade Information

- Cheque

- 1 Piece Per Day

- 1 Days

- No

- Sample costs shipping and taxes has to be paid by the buyer

- South America, North America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Australia, Central America

- All India

Product Description

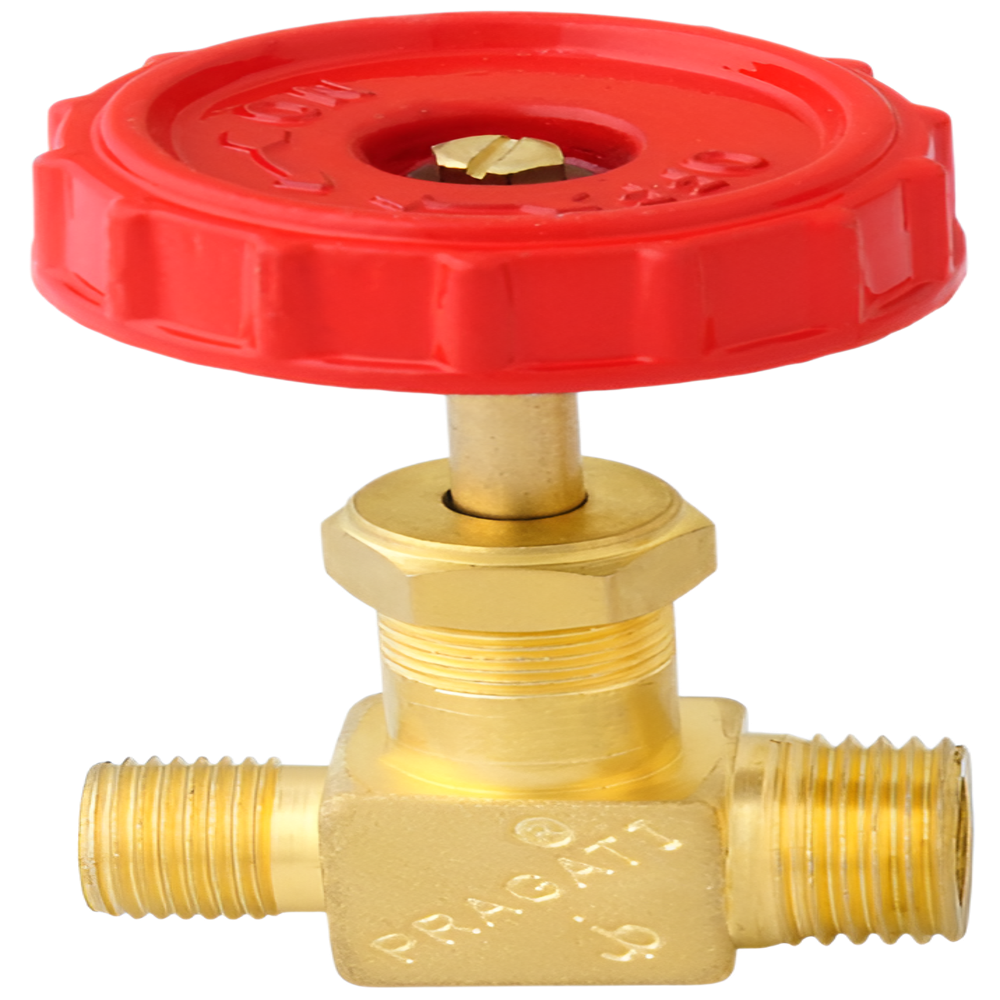

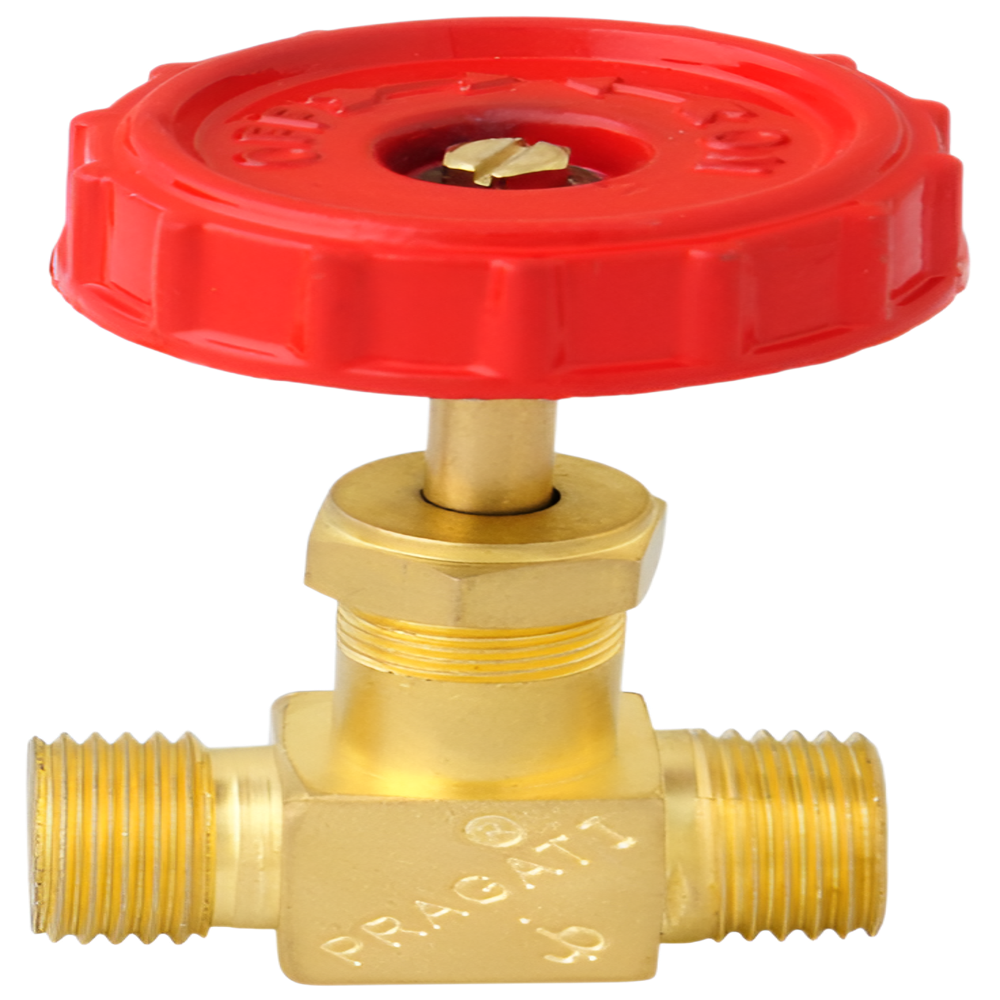

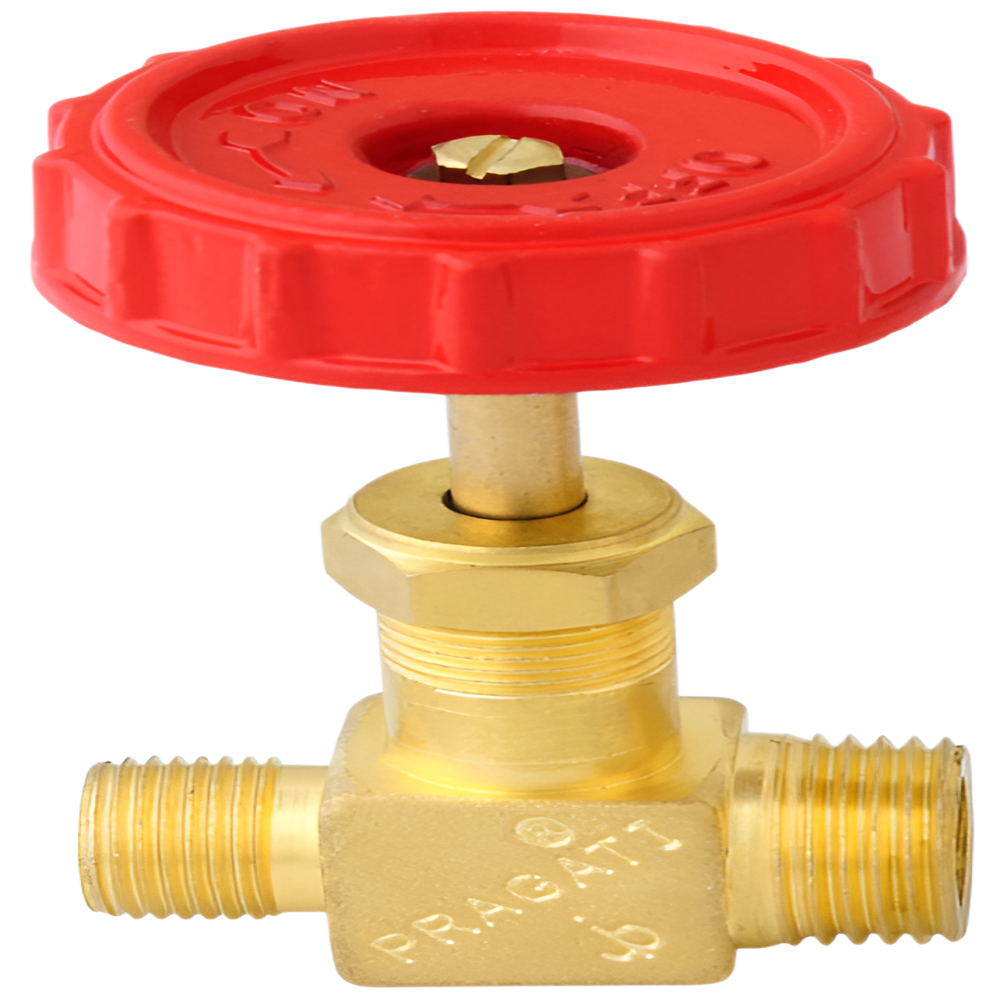

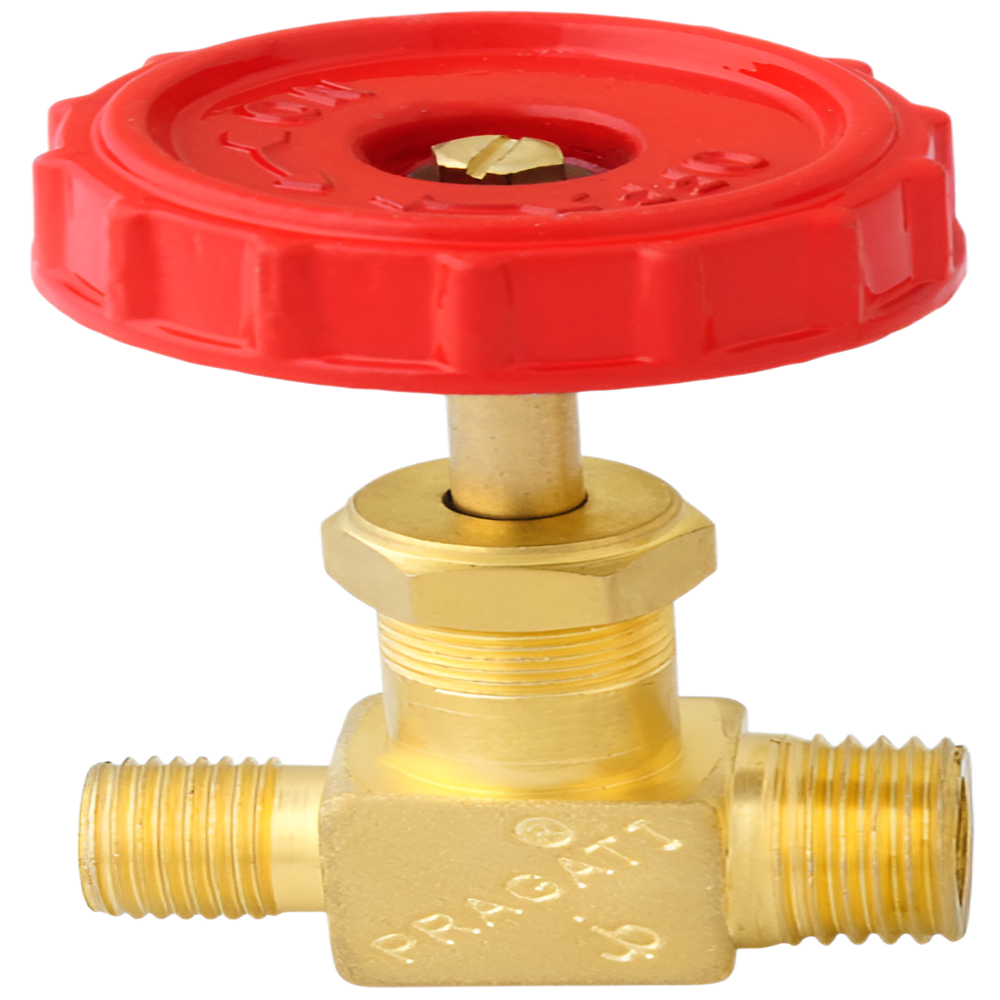

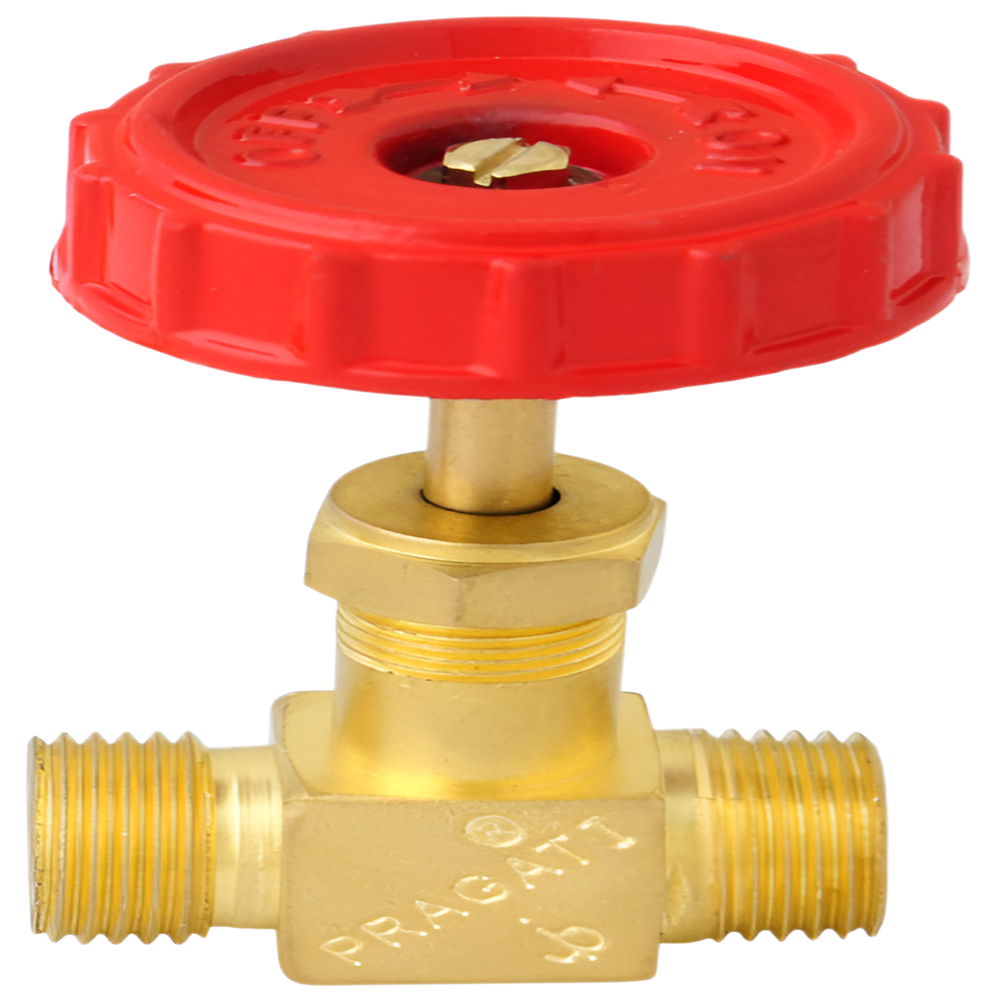

Brass Main Line Shut Off Valve

Material:

High-quality brass for durability and reliable performance in various applications.

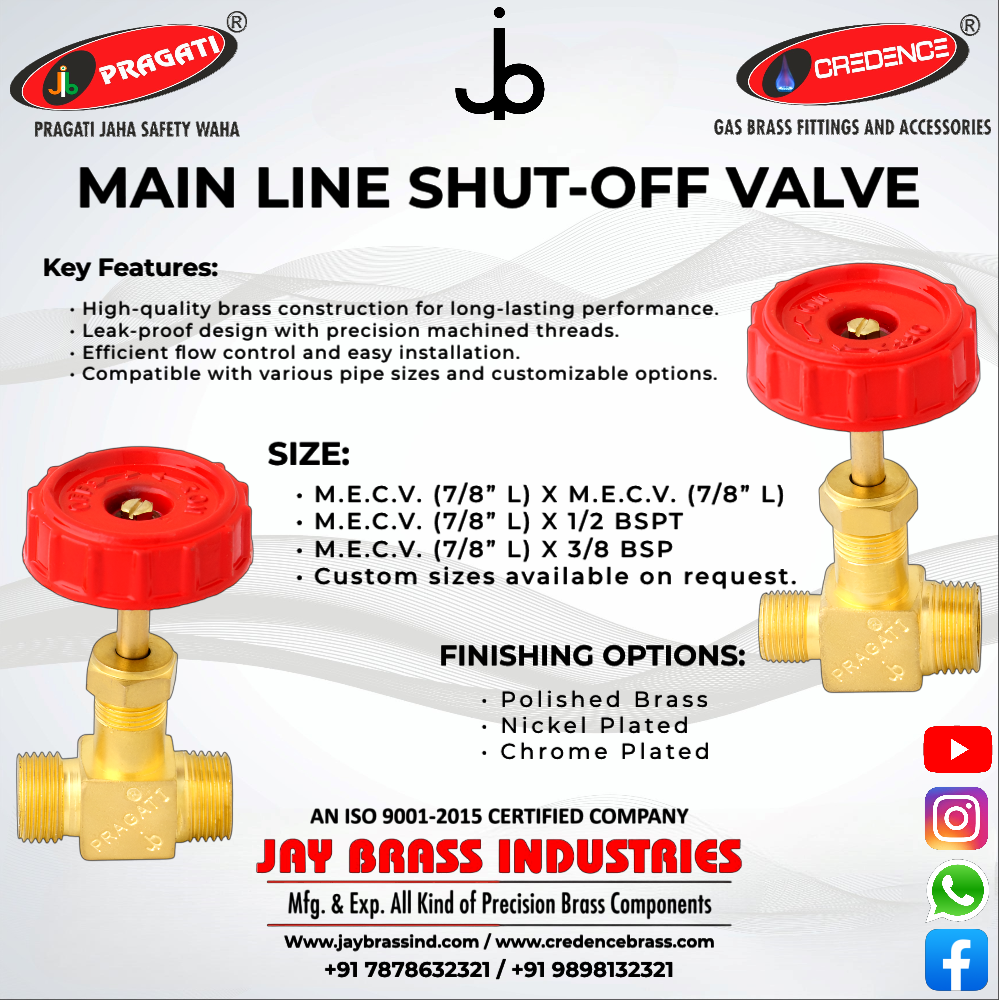

Key Features:

- Precision-engineered for leak-proof sealing

- Easy installation and maintenance

- Suitable for a wide range of industrial and commercial uses

- Provides effective control of fluid flow

- Resistant to corrosion and wear for long-lasting use

Product Variants:

- M.E.C.V. (7/8"L) x 1/2 BSPT

- 1/2 BSPT x 3/8 BSP

Custom Configurations:

Tailor-made options are available to meet specific requirements, providing flexibility for unique project needs.

Weight Options:

- M.E.C.V. (7/8"L) x 1/2 BSPT:195g

- 1/2 BSPT x 3/8 BSP:195g

Finishing Options:

Various finishing options available to match application needs.

Applications:

Ideal for use in plumbing, heating systems, gas lines, and other fluid control systems where efficient shut-off functionality is required.

Customization:

Customizable configurations for threading, size, and finish to suit particular operational demands.

Pricing Information:

Prices are indicative and subject to market conditions, order volume, and frequency. For an accurate quote, please reach out to us with your specific requirements.

Robust Performance Across Various Applications

Designed to handle water, gas, and air systems, these main line shut off valves deliver consistent performance under demanding conditions. Their corrosion-resistant and high-pressure metal construction makes them suitable for long-term use in commercial and industrial setups. Whether you install them as a distributor, exporter, manufacturer, service provider, supplier, or trader, these valves provide operational reliability and safety.

Flexible Connection and Easy Installation

With BSP and NPT threaded connections, these valves fit seamlessly into a variety of pipeline systems. Their precise 0.05 mm tolerance ensures accurate installation, minimizing the risk of leaks. Offered in a polished finish for extended durability, these valves can be requested with engineering drawings to match project requirements.

FAQ's of Main Line Shut Off Valves:

Q: How do I install a Main Line Shut Off Valve with threaded BSP/NPT connections?

A: To install the valve, ensure the pipeline is depressurized, then use compatible BSP or NPT fittings to connect the valve. Apply appropriate thread sealant to prevent leaks, tighten securely, and check alignment as per provided technical drawings if necessary.Q: What materials are used in the valve construction, and how do they benefit performance?

A: The valves use high-quality metals for the body, with NBR or PTFE seals for resistance to chemicals and pressure. These materials ensure high corrosion resistance and durability, even under extreme conditions, supporting a long operational life.Q: Where can these shut off valves be used?

A: These shut off valves are suitable for main lines in water, gas, and air distribution systems across residential, commercial, and industrial environments. Their IS-compliant design makes them ideal wherever reliable isolation and control are needed.Q: When is it necessary to use a shut off valve in a pipeline?

A: Shut off valves are crucial during maintenance, repairs, or emergencies to stop the flow in the system, ensuring safety and enabling efficient system management.Q: What is the operating temperature and pressure range of these valves?

A: The valves function reliably within a temperature range of -10C to 80C and can handle working pressures up to 16 bar, making them suitable for most standard industrial and utility applications.Q: How does the seal material affect the valve's performance?

A: NBR and PTFE seals offer excellent resistance against leakage and chemical degradation, ensuring stable sealing and extending the valve's lifespan in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Main Line Shut Off Valves' category

|

JAY BRASS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |